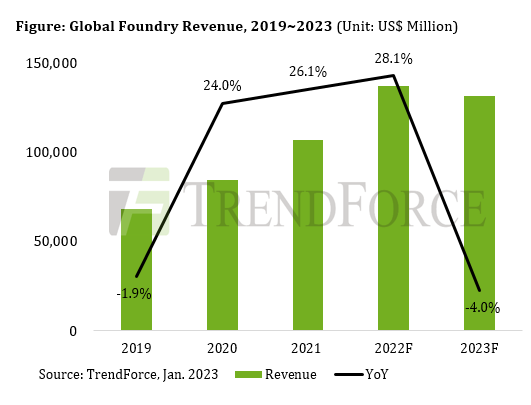

Demand continues to slide for all types of mature and advanced nodes.

The major fabless houses have cut wafer input for 1Q23 and will likely scale back further for 2Q23.

Foundries are expected to maintain a less-than-ideal level of capacity utilisation rate in the first two quarters of this year.

Some nodes could experience a steeper demand drop in 2Q23.

In H2, orders will likely pick up for some components that underwent an inventory correction at an earlier time.

8-inch wafer foundries’ capacity utilisation rates will remain mostly constant between 1Q23 and 2Q23. For now, TrendForce does not believe a substantial recovery will occur in the near future.

TSMC is expected to keep a less-than-ideal level of 11-inch capacity utilisation rate in 1H23. In H2 it should be able to have a limited raise of the rate of its 7nm node in 2H23.

TSMC’s 5nm node will eventually return to the optimal level in 2H23.

Samsung’s capacity utilisation rate will stay low for its ≤8nm nodes through 2023 chiefly because its main clients Qualcomm and NVIDIA have opted to reallocate orders to other foundries.

12-inch wafer foundries operating with mature nodes will mostly retain a capacity utilisation rate of 75~85% in 1H23.

These foundries, which include TSMC, UMC, and GlobalFoundries, are actively expanding into application segments that offer a more stable level of demand.

Examples include automotive electronics, industrial equipment, and medical devices. Thus, the mature nodes are able to maintain a relatively high capacity utilization rate.

TrendForce has also observed that the 28nm node has a higher rate compared with the 55/40nm nodes.

Furthermore, foundries that have a higher proportion of consumer-grade chips in the product mix have experienced a larger rate drop. Their rates have mostly dipped to around 65~75%.

The capacity utilisation rate will improve in 8- and 12-Inch Wafer Segments in 3Q23.

.