Although both come in a simple three-pin single in-line package, they are sophisticated digital processing ICs, and system-in-packages as they also incorporate a bias magnet and EMC protection components.

Crankshaft

The ATS16951 crankshaft sensor is designed to be a physical and electrical drop-in replacement for certain Hall effect crankshaft sensors.

It was developed for automotive safety-related systems as an ISO 26262 safety-element-out-of-context, and aimed at ASIL B capability (pending assessment) if used as prescribed in its safety manual and datasheet, said Allegro.

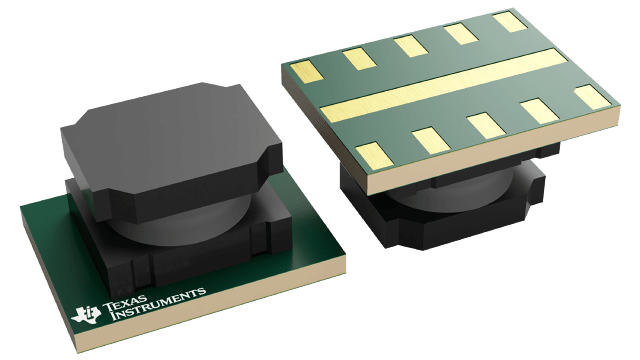

ATS16951 crankshaft sensor – the camshaft version is similar, but with only four sensors and a single input channel

ATS16951 crankshaft sensor – the camshaft version is similar, but with only four sensors and a single input channel

It includes a factory programmable pulse location between the centre or edge of the target feature, along with eeprom-programmable performance optimisations and production traceability.

“Up to 40% better edge repeatability and lower amounts of jitter” the company claimed compared with existing devices. “Its large air gap simplifies design-in, expands design margin and tolerance capability, and facilitates a wider range of sensor installation locations.”

Camshaft

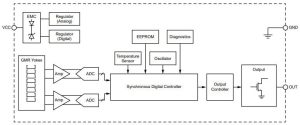

The ATS16351 camshaft sensor has a GMR bridge with a magnetic circuit that switches in response to magnetic signals induced by a ferromagnetic target. Differential sensing supresses the effects of stray fields.

It has a digital circuit that matches the temperature behaviour of the IC with the co-packaged magnet, and once inside the engine, an ‘auto true power-on state’ (TPOS) circuit learns the installed air gap and autonomously re-programmes the IC’s own internal switching threshold.

This sensor is “designed for the typical operating conditions found in automotive camshaft sensing applications”, said Allegro. “The resulting output of the device is a digital representation of the ferromagnetic target profile. It can be placed virtually anywhere, which is increasingly important as some hybrid engines now include four camshaft sensors,”

To assist OEMs, both sensors include ‘target profile diagnostics’ to asses the object-to-be-sensed when first installed in the host engine, before the engine is installed into a vehicle.

A wide range of factory-programmable options are provided to optimise parts for specific applications.

Product pages: