There are two chips: TLE9012DQU, the Li-ion battery monitoring and balancing IC, which can handle up to 12 cells in series, and TLE9015DQU which interfaces a microcontroller to a string of the monitoring ICs through an isolation transformer.

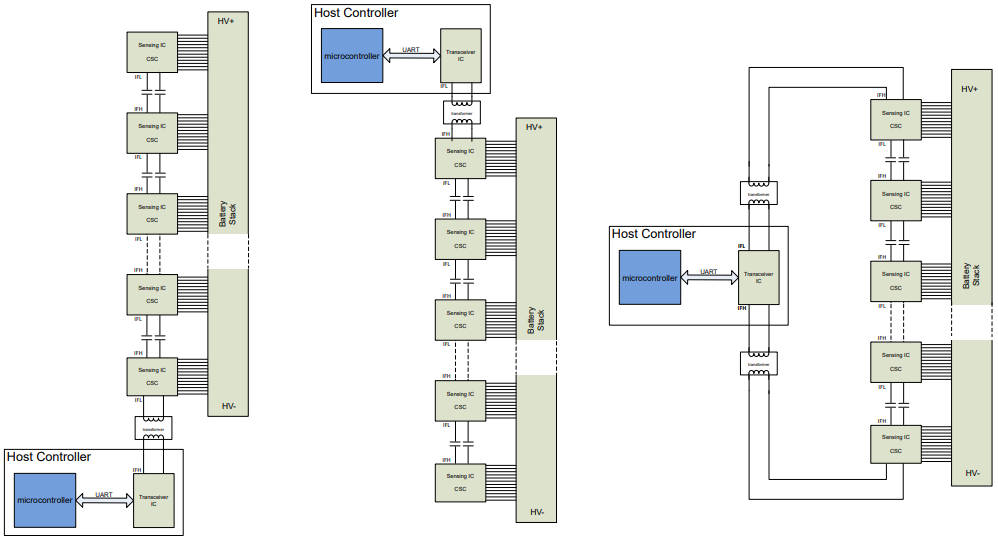

Depending on application, the ICs are designed to be able to operate in three configurations (see diagram): primary-on-bottom (‘PoB’, left), primary-on-top (‘PoT’, middle) or ring.

Communication up and down the stack is through linking dc-blocking capacitors using a 2Mbit/s protocol the company calls ‘isoUART’, and Infineon has appropriate interface software available for its own range of microcontrollers.

“The new battery management ICs can be used in safety relevant applications,” according to the company. “The solutions meet safety requirements up to ASIL-D and are ISO26262 compliant.”

The battery monitor IC has a dedicated 16bit ΔΣ ADC for each cell and circuits to implement passive (resistive heat loss) cell balancing.

There are also five temperature measurement channels for external thermistors, four GPIO pins that can be used to connect an external EEPROM, and internal diagnostics. It comes in a TQFP-48 package.

The MCU interface IC has two UART and two isoUART interface pairs to support all three potential configurations. Packaging is also TQFP-48.

As well as cars, use is foreseen in energy storage systems, two-wheelers and three-wheelers.