Researchers at Heriot-Watt University have improved a fibre-bundle endoscope in a demonstrated of laser-enhanced chemical etching, and developed a way to significantly speed up such 3d patterning of silica blocks prior to etching similar structures.

Polymer fibre endoscopes use a bundle of thousands of fibres, very carefully aligned at each end, to transmit an image at one end of the bundle to the other end.

Illumination can be provided by shining light down through the bundle from the viewing end, and displaying what bounced back.

But, said the university, when the illumination needs to be near the ultra-violet end of the spectrum, for fluorescence-based examinations for example, the fibre polymer itself fluoresces spoiling the contrast of the returning image.

Its answer is to use the outside few layers of fibres – around 18% of the 13,000 fibres in the 1.5mm diameter bundle, to send light down from the viewing end, and use the middle 82% (~1.4mm diameter) for viewing.

To turn the outside light inwards by 90° at the end of the fibre, to form a converging sheet of illumination across the face of the viewing fibres, an over-hanging circular 45° mirror was slid onto the end of the fibre bundle (see image above), and it is this accurate 3D mirror structure that has been fabricated at Heriot-Watt using its laser-enhanced etching technique.

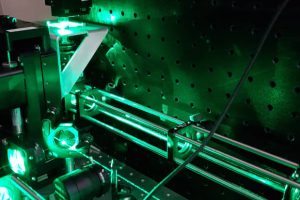

Laser-enhanced etching involves weakening the unwanted volumes of a silica block by exposing it to high levels of focused optical energy, after which the block is immersed in heated potassium hydroxide solution for a few hours.

With the right balance of laser exposure and etching conditions, unwanted material is preferentially removed at a rate of 1,000:1 compared to wanted material that has not been laser-exposed.

The silica shape was silvered to create the final reflective surface.

This is part of a project at the university, called 4MD, that has been funded though an EPSRC ‘Platform’ grant.

In a related part of 4MD at Hariot-Watt, scientist have speeded-up the laser exposure process 12-fold by moving away from the traditional Gaussian distribution of energy across the writing laser beam.

In a related part of 4MD at Hariot-Watt, scientist have speeded-up the laser exposure process 12-fold by moving away from the traditional Gaussian distribution of energy across the writing laser beam.

Their beam modification creates a ‘vortex focus’ in the beam – effectively a narrow (sub-wavelength) tube of high energy that has a distinct start and stop distance from the focusing optics – it actually tapers up to a maximum energy and tapers down again over a distance along the beam but, etched under the right conditions, the resulting hole looks as though it has been drilled.

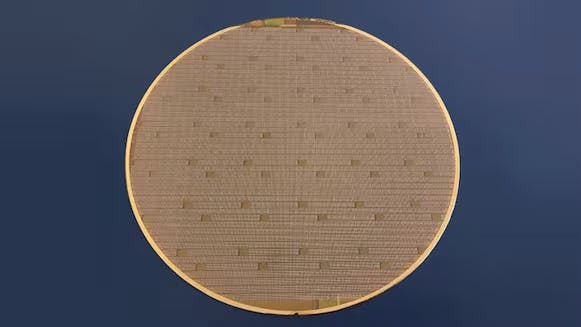

Key to the creation of this unusual in-beam energy distribution is the inclusion of a spatial light modulator – in this case a reflective modulator with ~1,200 x 1,000 phase-shifting reflective pixels spread over 16 x 13mm.

This is used to emulate the action of a conical lens called an axicon, which converts a bean with a Gaussian profile into one with a Gaussian-Bessel profile – which has this unusual length-limited concentrated narrow ‘vortex’ energy distribution.

As the axicon is virtual – being a 2D pattern of phase shifts across a flat spatial light modulator, rather than than a fixed physical object – its characteristics can be altered on-the-fly to lengthen and shorten the energy density along the beam as well as thinning and fattening it.

Pulsing the laser as the block-to-be-etched is moved underneath the focusing system allows overlapping columns of weakness to be shot into the silica block, that join together into a slot after etching, for example.

Features that took ~15 minutes to write using Gaussian focus, took 72s to write with vortex focus.

‘Investigating focus elongation using a spatial light modulator for high-throughput ultrafast-laser-induced selective etching in fused silica‘, in optical Express describes creating the vortex focus writing process, and goes some way to explaining what votex focus is.

A second paper, ‘Selective plane illumination optical endomicroscopy with polymer imaging fibres’, will explain the annular mirror and how it was made.