“This improves robots’ hands and grippers, making delicate operations such as fruit picking possible,” according to the Belgian company.

Uniquely, it said, it’s gradiometric approach makes it virtually immune from stray magnetic fields – a 2mT stray field only introducing a 0.3% of full-scale error – far better than any earlier magnetic-based 3D tactile sensor.

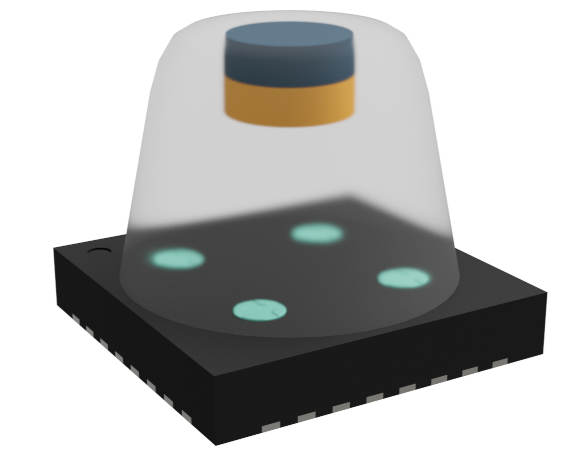

It is based around a 5 x 5mm four pixel magnetometer array (black in the diagram, and built from a pair of repurposed MLX90372 die set to a test mode) on to which a blob of 6mm diameter elastomer blob is deposited with a magnet (grey/yellow, 2mm diameter) embedded in the top.

Force applied to the grippy top moves the magnet slightly – either downwards with direct pushing or sideways with glancing contact.

Each of the four magnetic sensing pixels (magels? Ed.) is a 2d sensor set to detect components of the magnetic field across the surface of the IC and not perpendicular to it. Together then deliver eight signals: four from x-axis fields and four from y-axis fields.

From the changing fields on all four of the pixels, an algorithm built into the IC can extract the motion of the magnet, and therefore the force vector applied to it, while rejecting stray fields.

The algorithm is based on a polynomial model fitted to a calibration data set, and produces a force resolution of 2.7mN at the same time as rejecting the 2mT stray field, allowing it to, for example, easily detect a peanut balanced on top.

An on-chip temperature sensor and further algorithm allows operation from 0 to 50°C.

The sensor is described in detail in IEEE Robotics and Automation Letters as ‘A gradiometric magnetic force sensor immune to stray magnetic fields for robotic hands and grippers‘ The clearly-written paper can be read without payment.