Bombora Wave Power has completed indoor water tank testing of a floating energy platform that combines support for a wind turbine with wave energy harvesting.

Evaluated at the University of Edinburgh’s FloWave facility, “the integrated platform was tested under a wide range of conditions, including extreme waves”, said Bombora head of loads and modelling Peter Arnold. “Analysis is currently underway, where the results of the wave tank test are compared with those predicted using computational modelling.”

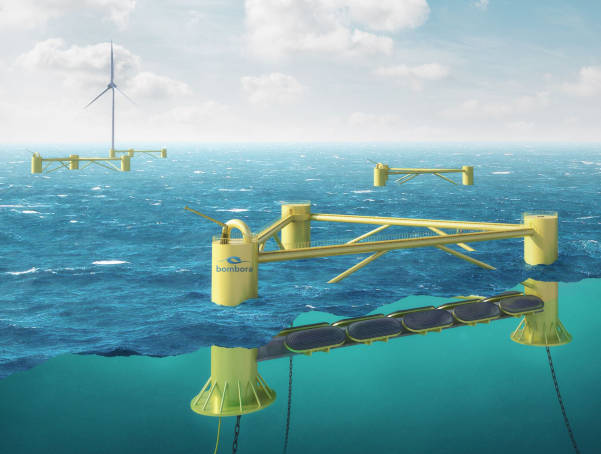

The tethered semi-submersible floating platform, dubbed ‘Inspire’ and designed by sub-contractor TechnipFMC, is intended to carry multiple ‘mWave’ (see below) wave energy harvesters just below the surface while having enough buoyancy and stability to hold a wind turbine aloft.

“The tank testing assessment will provide essential optimisation data leading to a detailed design of the combined Inspire mWave and wind wave platform due to commence early in 2023,” said Arnold.

MWave uses air-filled hollow vessels with flexible diaphragm lids held just below the sea surface, either anchored to the sea bottom (left) or on the tethered float.

MWave uses air-filled hollow vessels with flexible diaphragm lids held just below the sea surface, either anchored to the sea bottom (left) or on the tethered float.

Pressure variations caused as waves pass overhead are passed to the air in the vessels through the flexible diaphragm, and these air pressure variations are converted into uni-directional air flow within a closed loop manifold behind the vessels by rectifying valves. A turbine-generator converts air flow within the manifold into electricity.

“mWave has no external parts other than the flexible membrane,” said Bombora. “The membrane is made from industrial grade rubber – the long-standing use of similar materials in a range of marine applications has demonstrated reliability and longevity. In addition, mWave’s cell modules have an ability to shut down in extreme storm events to limit design loads.”

To get an idea scale, the company is designing towards a ‘Series 1’ float holding 4MW of mWave vessels and a 10MW wind turbine, followed by an 18MW-rated Series 2.

“By integrating wave and wind we can deliver more megawatts per square mile, providing a higher yield for seabed lease areas,” said Bombora CEO Dave Rigg. “mWave technology works as a natural partner to wind, helping to counter its intermittency and improve the overall power generation profile. In addition, this type of integrated design helps optimise project costs as mWave and turbine share the floating platform and mooring along with the export cables and grid connection.”

He added that the platform can be maintained using service vessels that catering to existing offshore wind oil and gas industries. The company is claiming it can achieve €60/MWhr levelled cost of energy at commercial scale.

A 1.5MW mWave demonstrator is due to be assembled at Pembroke dock, where Bombora is based, and installed in East Pickard Bay off the Pembroke peninsular in the next few months.

Bombora was one of seven technology developers awarded contracts for the first phase of the five-year EuropeWave collaborative R&D project, which will ultimately see three prototype technologies tested in 2025 at the European Marine Energy Centre (EMEC) in Orkney and the Biscay Marine Energy Platform (BiMEP) in Spain – the Edinburgh testing was part of EuropeWave.

EuropeWave is a pre-commercial procurement collaboration between Wave Energy Scotland, the Basque Energy Agency and Ocean Energy Europe, with match-funding from the European Commission’s Horizon2020 programme. Its has acces to €20m of combined national, regional and EU funding.

Founded in Perth Australia in 2012, Bombora’s key operations are now based in Pembroke Dock, Wales. It has a strategic partnership with Japan’s Mitsui OSK Lines to identify and deliver wave energy projects across Asia.